Structural Insulated Panels (SIPs) are becoming more common in New Zealand, especially for high-performance and Passive House builds. They offer faster construction, warmer homes, and lower running costs. But like any system, there are traps that can cost time and money if not handled well.

Based on what we’ve seen locally, and what’s been documented internationally, here are five pitfalls to avoid:

1. Pricing off the wrong set of plans

This is one of the biggest issues we see in New Zealand. Some clients try to get SIP pricing from sketches or concept drawings. Others spend heavily on full, council-ready plans before they know if the design is affordable. Both approaches can lead to wasted money and rework.

Better approach: Develop a good set of preliminary drawings. These give enough detail for accurate SIP costing, without the cost of full consent drawings. Once the budget is confirmed, you can move to working drawings with confidence.

2. Services not designed in

Electrical and plumbing need to be planned early with SIPs. Unlike timber framing, you can’t drill or cut as easily on site risking compromising the panels. Leaving services to the last minute can mean expensive workarounds.

Better approach: Agree on a services strategy during design — service cavities, pre-routed chases, or surface-mounted runs. This protects the panels and keeps the build on schedule.

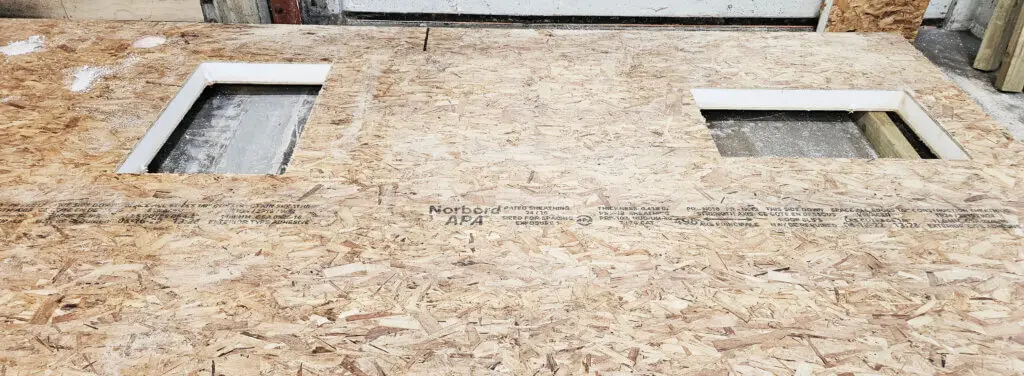

3. Airtightness and moisture risk at junctions

SIPs are airtight by design, but only if the joints are detailed and sealed correctly. Poor sealing at roof junctions in particular can cause moisture issues through condensation and air leakage.

Better approach: Follow the supplier’s tested junction details and use the recommended sealing products. A careful install makes the difference between an average build and a high-performance one.

4. Site conditions overlooked

NZ sites vary hugely, from salty coastal sections to alpine valleys. SIPs perform well in all climates, but roof pitch, orientation, and exposure still need careful design.

Better approach: Consider sun angles, prevailing winds, and rainfall at the concept stage. This ensures you’re getting the full benefit of SIP performance in your location.

5. Using non-certified or generic details

Not all SIP systems on the market are suitably appraised or certified, and not all details are equal. Using generic timber-frame assumptions or non-tested details can cause problems with compliance, performance, or even insurance.

Better approach: Always base drawings on the supplier’s appraised or certified details. This avoids redesigns, council RFIs, and gives confidence that the system will perform as promised

The takeaway: Most SIP pitfalls aren’t about the panels themselves — they’re about planning. With the right prelim drawings, clear service strategies, careful junction detailing, site-specific design, and certified details, you’ll save time and money and deliver a high-performance home that lasts.

Want to reach out about your project?

We’re free to discuss your build at any stage — from early sketches through to final plans. Contact us here.