Designing SIP Homes to Stay Cool in a New Zealand Summer

A slower market is the perfect time to build smarter. Clearer details, faster construction, simpler consenting, and lower risk. That’s where SIPpro panels make sense.

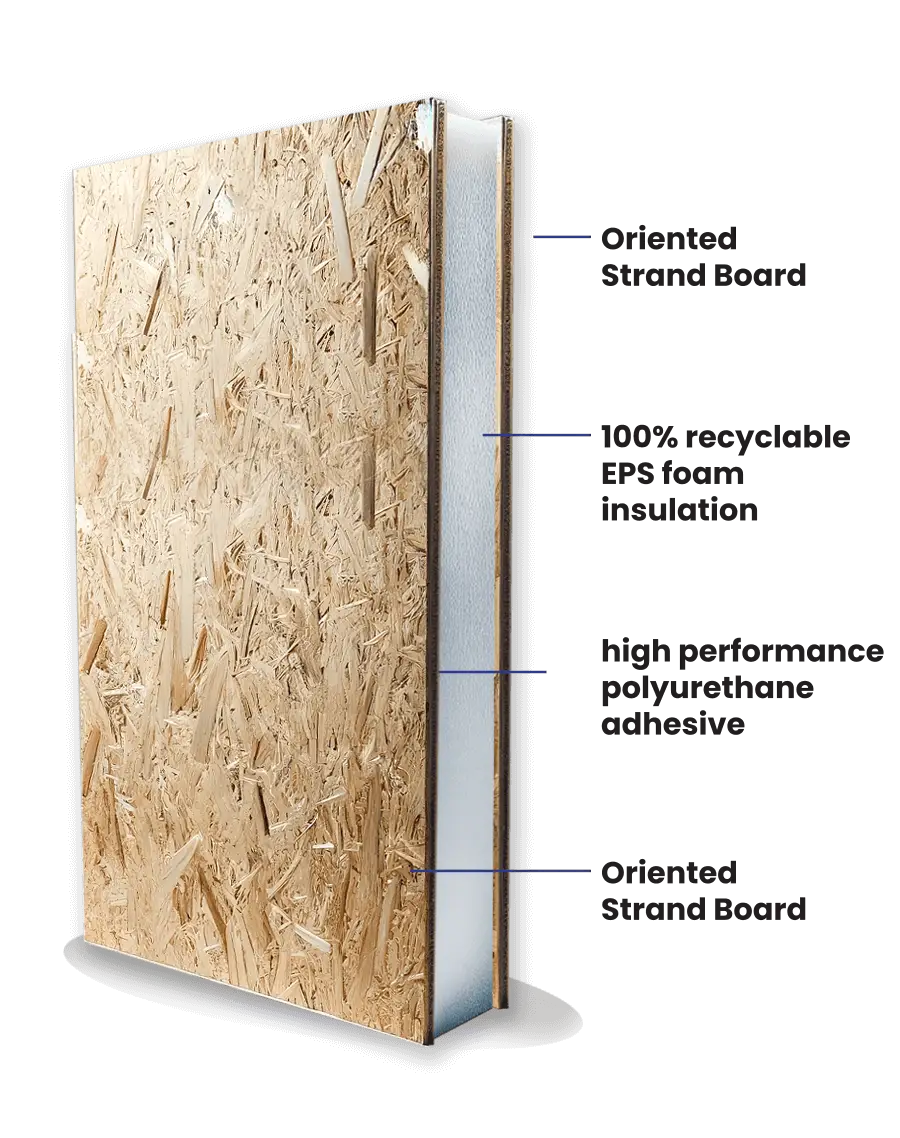

Structural Insulated Panels (SIP Panel) are innovative building components featuring two layers of oriented strand board (OSB) enveloping a rigid foam core, typically made from expanded polystyrene (EPS). This unique design ensures exceptional insulation, structural strength, and energy efficiency, making SIPs Panel a preferred choice in contemporary construction for both residential and commercial buildings.

Indulge in unparalleled comfort with SIP panels, not only enhancing your living space but also significantly reducing overall costs. Build faster and more efficiently, saving valuable time and resources. Enjoy substantial reductions in labor costs and less on-site waste for an eco-friendly construction process.

Based in the sunny Bay of Plenty, we are a dedicated supplier of SIP panels serving the North Island, committed to quality and innovation in sustainable building solutions. Embrace intelligent building solutions that not only expedite your project but also champion a more sustainable future. Opt for local excellence and build smarter with us.

Our panels, with a high-performance polyurethane foam core sandwiched between two layers of pressed board, ensure superior insulation and airtightness. The result? Consistently comfortable temperatures, reduced carbon emissions, and a healthier living environment.

Experience over 60% enhanced energy efficiency with SIP Panels compared to traditional timber framing. This translates to significant savings on heating and cooling bills. Moreover, our construction system ensures faster project completion, reducing overall build time.

Built for resilience, our SIPS panels offer greater strength and ductility than many conventional materials, making them ideal for areas prone to high winds or earthquakes.

Beyond just meeting standards, our SIPS panels set new benchmarks by significantly surpassing H1 requirements. This not only future-proofs your project but also ensures it aligns with the rigorous standards of the New Zealand Building Code of Compliance.

Embrace sustainability with SIP Panels. Our solutions align with evolving building codes, supporting New Zealand’s carbon neutrality commitment. We prioritize sustainability in our operations, generating less waste compared to timber framing, with fully recyclable Expanded Polystyrene.

Every project is unique, and so are our solutions. Our factory collaborates closely with clients to manufacture and deliver panels tailored to specific requirements. With state-of-the-art machinery at our disposal, we can produce oversized panels suitable for any project scale.

SIP panels are a versatile building system that allows seamless integration with traditional timber framing, masonry block, concrete, structural steel and timber trusses. For example, architects and builders often use SIPs highly insulated walls on top of a concrete floor with timber trusses supporting the roof.

Our SIP Panels employ sustainable EPS foam insulation (Expanded Polystyrene). Comprising 98% air, EPS is fully recyclable and delivers excellent R-Values for your project that lasts the lifetime of the building. After much research we determined EPS provided the best insulation performance vs cost over a building’s lifetime. Other foam products such as PUR foam release VOC’s (Volatile Organic Compounds) called off-gassing which is unhealthy, and this reduces its thermal R-Value performance over time (Thermal Drift). Also, PUR cannot be recycled easily in New Zealand. We prefer EPS, which is completely non-toxic, safe and readily 100% recycled in New Zealand. We offer both standard white EPS and top-tier carbon-treated Neopor EPS. Neopor offers 20% better thermal performance than white EPS allowing higher R-Values, thinner roofs and walls when needed. Neopor FR Flame Retardant EPS and standard white EPS have been tested for flame propagation and they comply with AS 2122.1-1993. The flame retardant reduces the flammability and the spread of flame of the surface of the foam if an ignition source comes in direct contact with the foam.

As SIP Panels are pre-manufactured, they do need a lead time, typically between 2 to 10 weeks depending on the scale and complexity of the project. For accurate planning, we suggest reaching out for a quote before initiating on-site work.

SIP homes offer a much faster construction timeframe compared to traditional timber and steel framing methods. With a proficient Structural Insulated Panels (SIP) installation team, framing time can be reduced by up to 55% compared to conventional timber and steel framing. For example, when our SIP panels are stood up on site and fixed into position, they already have the insulation, earthquake/wind bracing, and external rigid air barrier (RAB) installed. This is very fast when compared to a precut timber framed house which at this point still needs insulation, external rigid air barrier and insulation, earthquake/wind bracing installed. Our SIP panels are delivered as whole or partial pre-cut, ready to assemble floor, wall and roof panels. These can be positioned quickly, making it possible to assemble a weather-tight, highly insulated, airtight, floor, wall and roof shell in a few days. As our SIP panels already have the insulation, earthquake/wind bracing and external rigid air barrier (RAB) fitted, the time needed to install those systems into traditional timber and steel framing is saved. Your builder just needs to wrap the panels with high-performance building wrap to ensure weather tightness.

SIPs homes offer complete insulation and outstanding energy efficiency, making it easier to achieve the Passivhaus standard of airtightness and energy efficiency. Thanks to the enduring nature of SIPs, the EPS insulation remains consistent and fully effective over time, ensuring an even and lasting insulation performance for the life of the building. When SIPs panels are employed in the roof, timber trusses are not required, the absence of trusses enables the conversion of attic space into living areas with the addition of roof windows, dormers and skylights, offering families the opportunity to expand their living space at a minimal extra cost.

Our SIP panels come in dimensions of 2.44m x 1.22m increasing in size up to a maximum of 7.32m in length and 2.44m in width. Our ready to assemble (RTA) SIPs are custom cut to suit the requirements of the design. Tight and compact sites can be provided for compact panel sizes to best suit access, handling, and installation. Talk to us about your project’s requirements. Our design advice and shop drawing services can cater to your requirements.

SIP panels can endure for the entire lifespan of the building. Unlike polyurethane foam (PUR), EPS exhibits almost no degradation or deterioration over time, potentially offering a longer lifespan than conventional building methods. The New Zealand building code requires all housing to be designed to last 50 years. SIPs panel meet and exceed this requirement.

A slower market is the perfect time to build smarter. Clearer details, faster construction, simpler consenting, and lower risk. That’s where SIPpro panels make sense.

A slower market is the perfect time to build smarter. Clearer details, faster construction, simpler consenting, and lower risk. That’s where SIPpro panels make sense.

Receive our latest blog posts directly in your inbox!