SIPpro panels are more than insulation and timber squashed together. Each panel is a factory-made building unit, structural, insulated, airtight, and braced. Put together properly, they create walls, floors, and roofs that are faster to build and higher performing than traditional framing.

Here is the simple version of how SIPpro panels go together on site.

1. Bottom Plates, The Track for the Panels

Every SIPpro wall starts with timber bottom plates fixed to the slab or floor system.

- Plates are bolted down to NZS 3604 requirements or SIPpro’s fixings schedule.

- A damp proof course (DPC) runs under the plates.

- SIPpro adhesive and low-expansion foam are used to seal the joint where panel meets plate

Pro tip: Council inspections will check bottom plate fixings before panels hide them, so get this step right the first time.

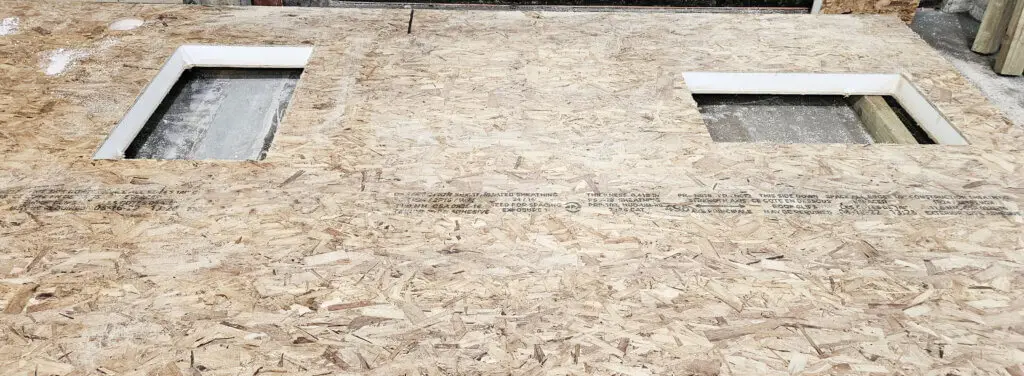

2. Standing the Panels, Slot, Glue, Screw

When it is time to stand the walls, panels are lifted into place and joined together using splines inside the insulation recess.

- Timber stud splines provide structure.

- Thermal or composite splines improve insulation continuity.

- All splines are set in SIPpro adhesive, nailed or screwed at the specified centres, and foamed to seal insulation-to-insulation contact

Pro tip: Plan your bracing early. SIPpro can provide extra-long bracing panels and also offers 600mm bracing panels so you can still brace properly around windows or smaller wall runs.

3. Locking the Walls, Top Plates and Bracing

Once panels are standing, a timber top plate is recessed into the panels and fixed with nails, screws, adhesive, and foam. This ties the walls together as one continuous structural unit.

Bracing panels use galvanized steel strap hold-downs connections, along with M10 bolts that fix back into the slab or floor joists

Pro tip: Mark with a pencil the position of all the wall panels onto your floor and write the panel number at each location using your panel setout drawings provided.

4. Adding the Roof, Fast and Strong

SIPpro roof panels are craned onto the top plates and secured with SIP fasteners at 300 mm centres.

- At ridges, valleys, and eaves, junctions are reinforced with adhesive and SIPpro screws.

- Vapour barrier tape is laid over ridge and beam connections before panels go down to ensure airtightness.

Pro tip: Because SIPpro roof panels can span large distances, entire sections can go on at once. Schedule cranage carefully and you can bring a build to weathertight in days, not weeks.

5. Sealing for Airtightness

This is where SIPpro’s performance edge really shows. Every joint, corner, and penetration is sealed with SIPpro Vapour Barrier Tape (VBT) on the inside. On the outside, panels are wrapped in a vapour-permeable underlay before cladding or roofing is installed

Pro tip: Do a blower door test before linings go on. It is the easiest way to find leaks and fix them while everything is still accessible.

6. Services, Built In, Not Cut In

SIPpro panels can be factory-supplied with electrical chases and socket cut-outs. This saves time on site and avoids weakening the panel.

- Use service cavities or internal walls for plumbing.

- Do not cut large slots or recesses in the OSB face.

Pro tip: Always plan ventilation. SIP buildings are extremely airtight, which is great for energy savings, but it means MVHR (mechanical ventilation with heat recovery) is essential for healthy indoor air.

7. Designed for Efficiency

SIPpro panels are available up to 7.32 m long by 2.44 m wide, in standard thicknesses from 115 mm to 315 mm (R-values from R2.8 to R9.7)

Designing in module sizes of 300, 400, 600, and 1200 mm minimises cutting and waste.

Energy modelling your SIPpro home before you build is like test driving it on paper. It shows how insulation, airtightness, window placement, and ventilation will perform and avoids costly surprises once the panels are up.

Pro tip: Investing in energy modelling early gives you a clear picture of comfort and performance, and helps you avoid overspending on heating or cooling systems later.

Why Builders Choose SIPpro

- Fast to erect, walls, insulation, bracing, and rigid air barrier all in one step.

- Stronger than it looks, the OSB skins and EPS core act like an I-beam.

- Airtight and warm, taped and sealed panels cut heat loss and drafts.

- Precision made, factory-cut panels mean straighter walls and faster lining.

In short, SIPpro panels go together by combining adhesives, splines, fixings, and airtight tapes into a single, continuous envelope. They are simple to slot together, but the details such as sealing joints, planning bracing, pre-cutting services, and testing airtightness are what take them from “just panels” to high-performance buildings.

Contact our team here at SIPSolutions to arrange a design check and make your build as smooth as possible.